Our sales team is ready to help you find the right product for every unique situation.

CONTACT US

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.

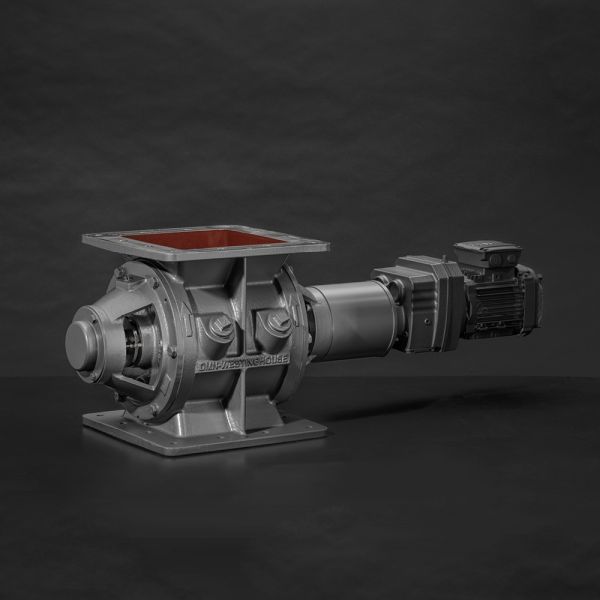

AL/AXL

Drop-through

All-round rotary valve for metering and conveying powders and granules

AL/AXL

Drop-through

All-round rotary valve for metering and conveying powders and granules

AML

Drop-through

All-round rotary valve with one round and one square flange

AML

Drop-through

All-round rotary valve with one round and one square flange

USAL

Drop-through

All-round rotary valve with two square flanges

USAL

Drop-through

All-round rotary valve with two square flanges

GL

Drop-through

Granular rotary valve for gravity feed or pneumatic conveying

GL

Drop-through

Granular rotary valve for gravity feed or pneumatic conveying

NR347

Drop-through

Exact fit for replacing your Niro rotary valve

NR347

Drop-through

Exact fit for replacing your Niro rotary valve

SAL

Drop-through

Heavy-duty sanitary rotary valve

SAL

Drop-through

Heavy-duty sanitary rotary valve

BL/BXL/BXXL

Blow-through

Precision metering and pneumatically conveying with a modular design

BL/BXL/BXXL

Blow-through

Precision metering and pneumatically conveying with a modular design

MZC-I

Drop-through

The standard in safety, hygiene and cleanability opens on one side

MZC-I

Drop-through

The standard in safety, hygiene and cleanability opens on one side

MZC-II

Drop-through

The standard in safety, hygiene and cleanability opens on two sides for easy accessibility

MZC-II

Drop-through

The standard in safety, hygiene and cleanability opens on two sides for easy accessibility

MALD/MLD

Drop-through

Ideal for vacuum conveying, bulk bag unloading, cyclone applications, and general-purpose use

MALD/MLD

Drop-through

Ideal for vacuum conveying, bulk bag unloading, cyclone applications, and general-purpose use

DL

Drop-through

Dust lock rotary valve designed for filter applications

DL

Drop-through

Dust lock rotary valve designed for filter applications