Our sales team is ready to help you find the right product for every unique situation.

CONTACT US

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.

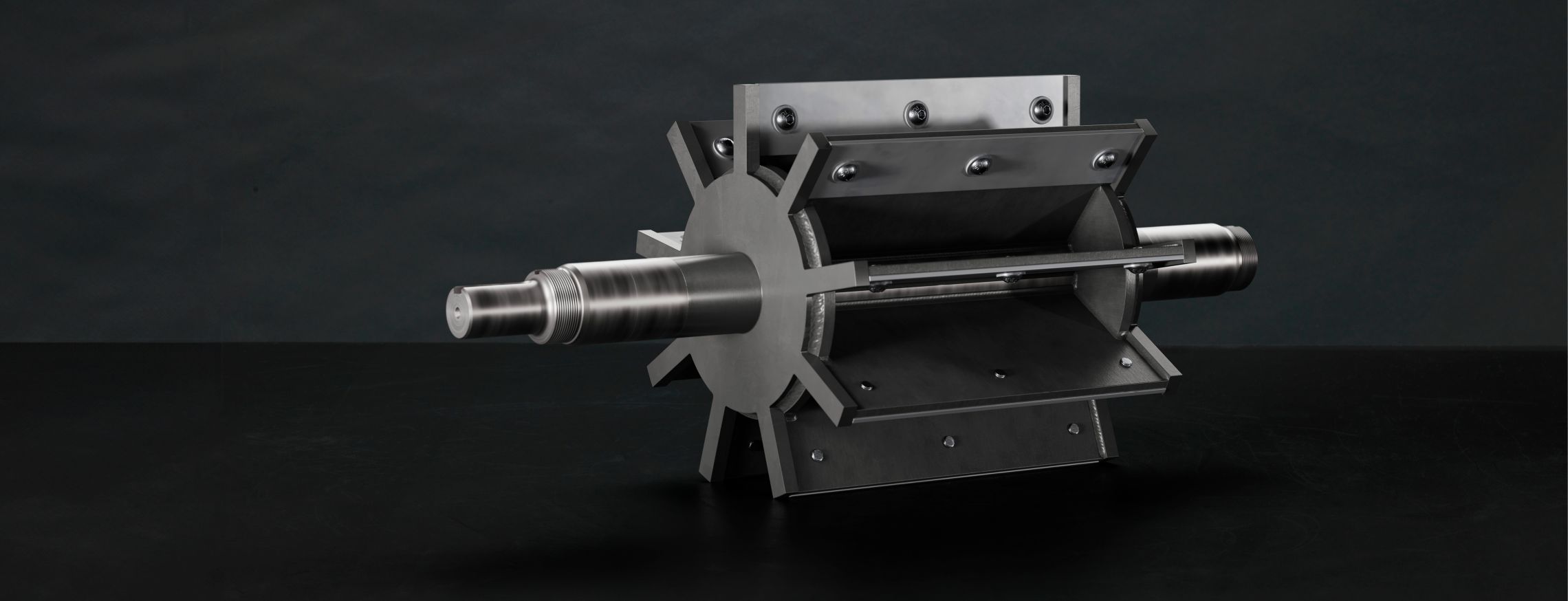

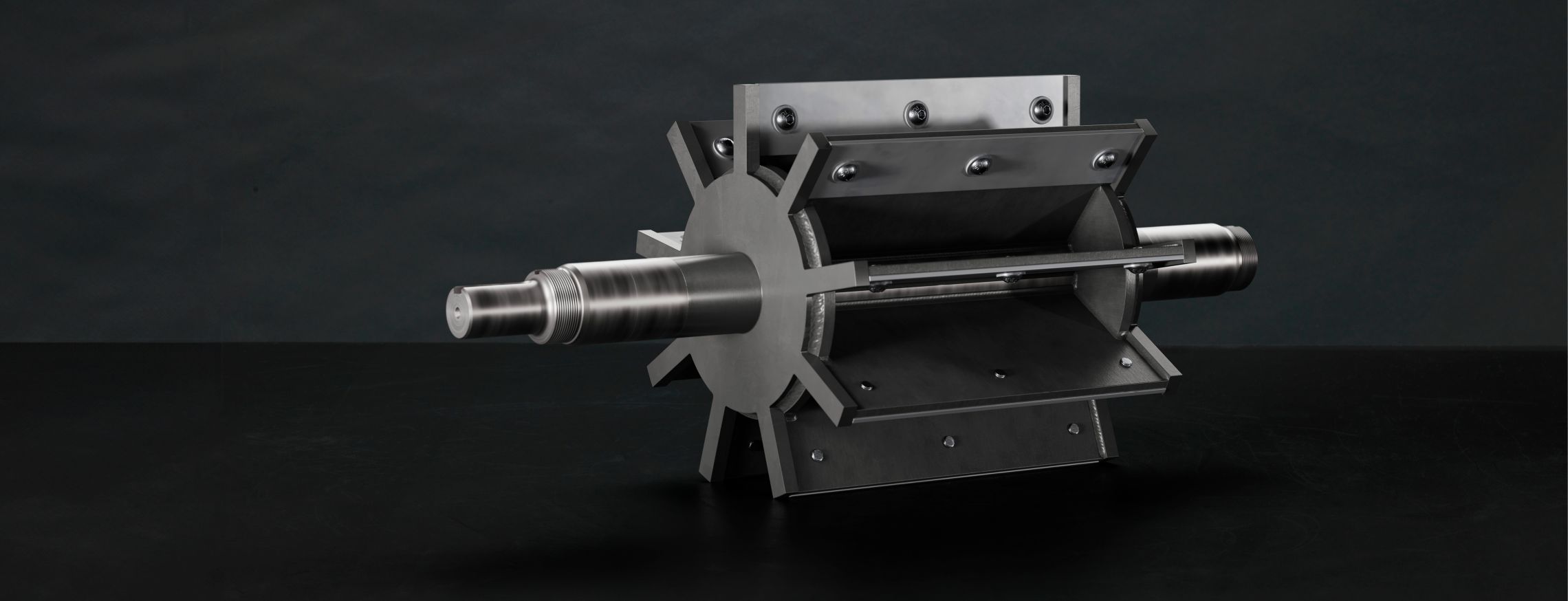

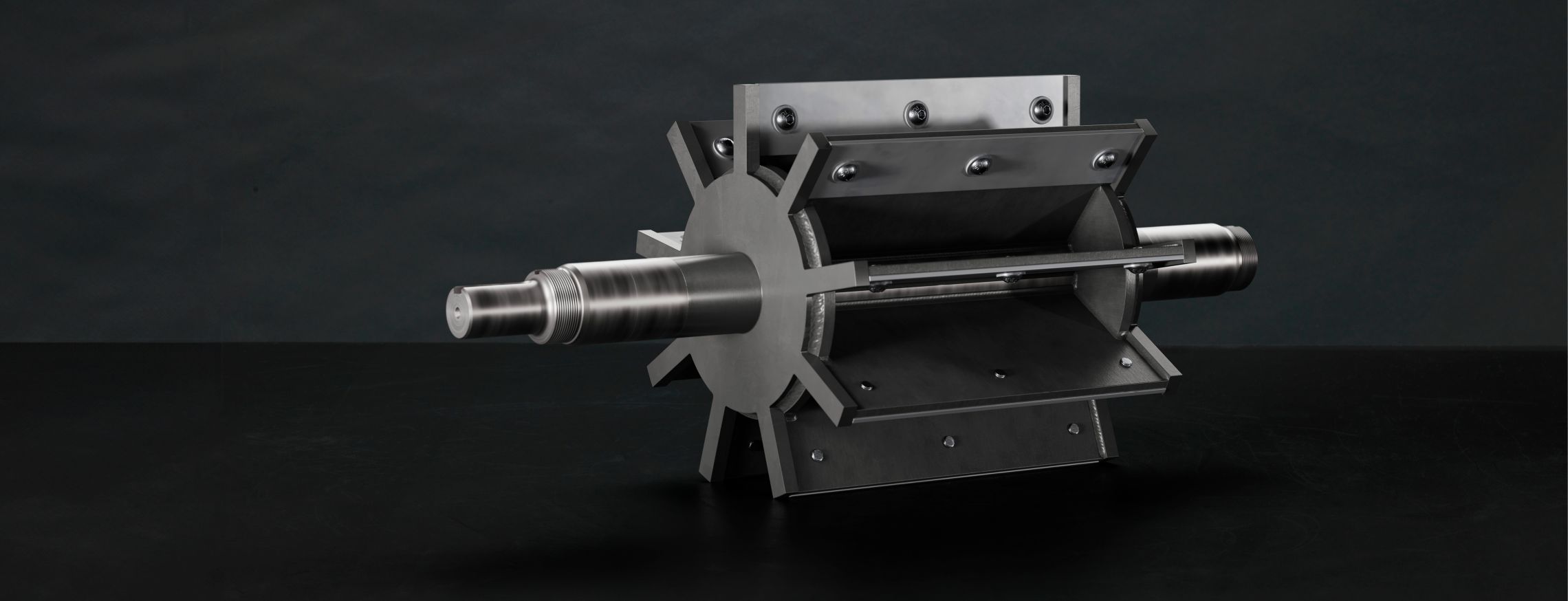

Discover our latest addition to the wear-resistant rotor family; alongside our regular 4TCO and 4TS rotors, we now feature the incredible Resilient Edge (RE) Rotor. A true powerhouse in wear resistance, the RE Rotor derives its name from the reinforced vane edges, which protect the end covers whilst preventing wear by friction from product caught between plates.

Of course, no rotor is entirely safe from wear. However, by distributing friction evenly across the entire end cover surface, our RE Rotor ensures minimal wear while allowing easy maintenance and wear management. The protective end plates and vane edges can easily be repaired, re-machined and re-coated or, in extreme cases, even replaced without replacing the entire rotor. The RE Rotor can be used with AL and BL rotary valves in pressure conveying systems, handling highly abrasive powders, fine grits, or friable granules. Think of heavy industries handling minerals, aggregate production, and chemicals. The RE Rotor is available in sizes 200, 250 and 300.

Thank you

Your quote request has been received!

Something went wrong.

One moment..

Thank you!

We have received your message and we are looking forward to be in touch with you.

Something went wrong.

One moment..