We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.

Morris couplings provide an economical connecting method of joining conveying pipes together. The Morris coupling range is serving the pneumatic conveying industry with a complete line of precision quality coupling and tubing products. They can be used in both pressure and vacuum applications. Installation usually requires no special preparation of the pipe ends. Only de-burring, removing of any scale and degreasing of the portion of the tube to be clamped.

Compression Couplings

Compression CouplingsThe ‘Original’ Morris compression coupling designed to join pipe and tubing for pneumatic conveying systems. Features:

Gasket protector

Gasket protectorProvide positive gasket protection against abrasion or erosion in pneumatic conveying systems. Eliminates:

Light-duty (LD) Compression Coupling

Light-duty (LD) Compression CouplingFor vacuum conveying systems. Similar in design to the ‘original’ Morris compression couplings, except manufactured of lighter gauge steel and bar washers. Features:

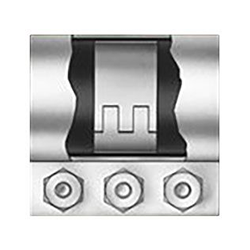

Side-band compression couplings

Side-band compression couplingsMaximum holding power to connect pipe and tubing. Unique design with:

Quickon II Single and dual couplers

Quickon II Single and dual couplersQuick and efficient installation or removal of pneumatic and vacuum conveying lines or systems with a twist of the wrist. No tools required. Applications provides:

In-line sight glasses

In-line sight glassesProvide a 360° full-view window to observe material fl owing through pneumatic or vacuum conveying lines. Features:

Thank you!

Something went wrong.

One moment..