Our sales team is ready to help you find the right product for every unique situation.

CONTACT US

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.

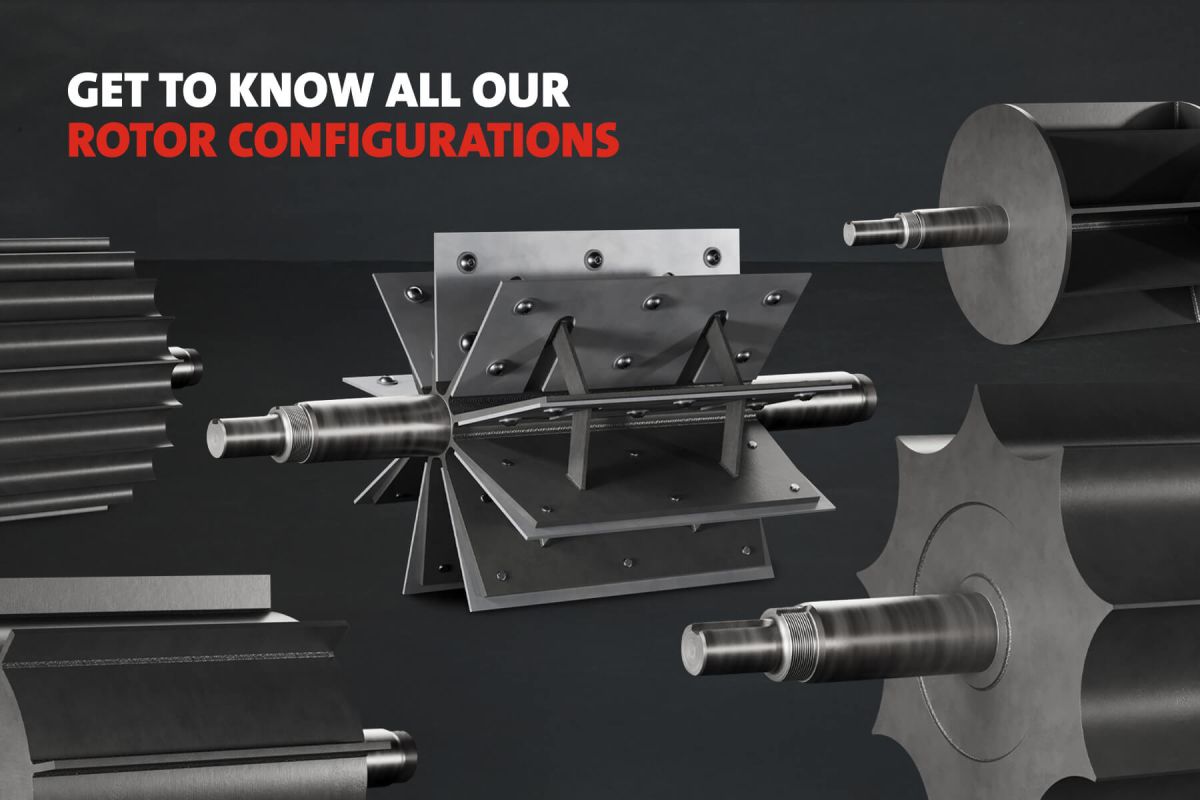

At DMN-WESTINGHOUSE, there is a vast choice of rotors. And rightly so, as precision and efficiency are essential in the world of dry bulk solids handling. DMN-WESTINGHOUSE offers 8 unique rotor options for rotary valves, each designed to optimise the performance and safety of a production process.

Whether dealing with powders or granules, the right rotor not only increases reliability but also improves the hygiene of the process.

Discover how each rotor contributes to consistent product flow and maximum effectiveness in various processes.

How the right rotor choice makes a significant impact

Choosing the right rotor is crucial to ensuring the efficient and reliable operation of rotary valves. Rotors not only regulate product flow and dose materials, but they are also key to preventing downtime and unnecessary maintenance. In demanding environments where wear resistance and corrosion protection are paramount, selecting a rotor that is carefully matched to the application optimises operational effectiveness, reduces maintenance costs, and increases the reliability of the entire production process. Let’s dive in.

Fixed Vanes: an all-round component

The Fixed Vanes rotor option consists of fixed blades to ensure stable and continuous product flow for powders and granules. Its robust construction is ideal for high-pressure and high-temperature applications. The chamfered blades reduce surface friction, improving efficiency. These all-round components suit various industries, such as pharmaceutical, food, and chemical sectors. The hygienic design minimises product build-up, while radius pockets assist in discharging sticky or hygroscopic products, reducing cleaning frequency.

Replaceable and Adjustable Blades: flexible and durable

Replaceable and adjustable blades offer flexibility and make it easy to replace blades without disassembling the entire rotor. Depending on the application, different materials can be chosen: steel and hardened steel are suitable for abrasive materials, stainless steel for corrosion resistance, polyurethane for non-fragile products, and scrapers for sticky substances. If extra support is needed for hard products like lactose and PVC powder, support beams can be added.

Resilient Edge: the go-to for wear-resistant performance

The Resilient Edge rotor option is designed for heavy-duty applications where wear-resistant performance is crucial. This option features reinforced, flexible edges on the rotor blades, ensuring better sealing and reducing air leakage, which is vital for fine powders and abrasive materials. The reinforced blade edges protect the end plates and evenly distribute friction, minimising wear and damage to the rotor and the product. This results in a longer lifespan and less maintenance. The protective end plates are also easy to repair, making the Resilient Edge the ideal choice for sectors where wear is a constant challenge.

Semi End Disc with replaceable and adjustable blades: adaptable and simple

The Semi End Disc rotor with replaceable and adjustable blades is a powerful solution for processing abrasive materials, offering extra protection against wear. This rotor option, standard for the 4TS model, allows users to easily replace the blades without disassembling the entire rotor. This makes it particularly suitable for processes where adaptability and efficiency go hand in hand.

End Disc Fixed Vanes: robust wear protection

The End Disc Fixed Vanes are designed explicitly for processing palletised products, such as plastic pellets. The robust fixed blades on the rotor's end discs provide a stable structure that minimises wear on the end caps.

Reduced Capacity Closed End: for challenging bulk materials

The Reduced Capacity Closed End rotor option is developed for handling bulk materials with challenging flow properties—whether due to stickiness or particle size—requiring an abnormally large inlet opening. By reducing the capacity of the rotor pockets and adding closed ends, the accuracy of material transport is significantly improved.

Scalloped Pockets: smooth handling for sticky situations

The scalloped pockets in the rotor minimise product build-up and promote even material distribution. This design is particularly effective for sticky and hygroscopic products that are prone to sticking or clumping, such as powders with high cohesion.

Fine Dosing: precise control for specific applications

The Fine Dosing rotor option is ideal for applications requiring precise dosing, especially in the food and pharmaceutical industries. The rotor blades are specifically designed to consistently transport small amounts of valuable active ingredients without compromising product quality or throughput speed. Thanks to this precision, the Fine Dosing rotor is effective in handling sensitive and expensive products where a high level of accuracy is essential.

Our rotor process solutions: boosting your processes

Choosing the right rotor is essential for the efficiency and reliability of material handling systems in the dry bulk goods industry. DMN-WESTINGHOUSE provides expert support to help you select the most suitable rotor option for your specific applications. Together, we can consider important factors such as material properties, process conditions, hygiene and regulations, and operational efficiency to find the best rotor choice for your company’s specific needs and requirements.

Want to learn more about our rotors? Contact one of our offices or your contact person.