We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.

Thank you!

We have received your message and we are looking forward to be in touch with you.

Something went wrong

One moment..

In dairy production, product quality and product safety are of the utmost importance. That’s why most dairy producers worldwide rely on the products and solutions of DMN-WESTINGHOUSE. Our rotary valves and diverter valves offer the highest level of precision workmanship, preventing bridging and product contamination during conveying processes. In addition, we provide unparalleled cleanability thereby reducing downtime for maintenance and repairs.

We know the dairy industry

Specialising in handling dry bulk materials for the dairy industry, DMN-WESTINGHOUSE

is your trusted partner in delivering unparalleled efficiency and safety. Our commitment is underscored by our compliance with all essential certifications, including USDA, EHEDG-ED Class II, and ATEX.

At DMN-WESTINGHOUSE, we are dedicated to keeping your business going.

Today and in the future. Our rotary valves and diverter valves meet and exceed

the highest standards in the dairy industry.

“The MZC is a very hygienic and clean rotary valve. You can take that rotor out in a minute, clean it, and put it back in. The biggest challenge in the dairy industry is the downtime for cleaning. It can take 30 minutes to clean a valve, but there are also cases where they spend half a day trying to clean the valve out. That shuts down the production line. For a big company like Hershey, processing 30,000 pounds an hour of peanuts to produce peanut butter, that's about a million dollars a day lost. In my opinion, that decides for fast-cleanable valves like DMN-WESTINGHOUSE’s. Bargaining over saving a few thousand dollars by purchasing another brand is just not worth it.

Bridging is a common phenomenon in dairy. Every valve has a specific pocket fill capacity. Certain products, like baby formula have a certain content of fat. So, they have a higher angle of repose and tend to slowly build up in the pockets. This continues to the point where it bridges, and you are left with pockets that are working and pockets that are not. So, the valve can rotate and there'll be a lot of material on its way, but it won't move. And then the rotor must be taken out and cleaned.”

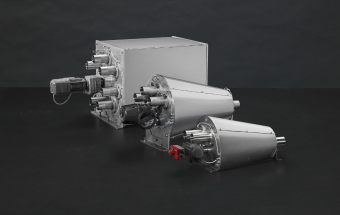

We offer a diverse array of rotary valves and diverter valves, each meticulously customised for dairy applications. This tailored approach ensures our valves meet the unique requirements of different dairy processes, consistently delivering proven performance and reliability.